Bance Shims are manufactured on unique special purpose machinery to tight standards of tolerance. They are made from a grade of steel specially developed for their application in the rail joint, which requires a material that has considerable toughness, yet is compatible with both rail and fishplate. Six sizes of thickness and angle of taper and manufactured to suit all degrees of wear, in three standard designs – Types “F”, “S” and “HL” – to accord with the usage required. All Shims are made specially to suit the rail section to which they are needed.

Type “HL” Half Shim With Lip

Type “HL” Shims are recommended for use in a joint where the wear in one rail end varies from the wear in the other as is normal for single direction traffic. The lip enables the fitting operation to be carried out more easily. When fitted the lip is bent down to hold the shim in position when later the joint is dismantled for maintenance. The lip also enables quick inspection, showing at a glance that joints are shimmed correctly.

Standard Dimensions (subject to our shop tolerances)

| Shim No | Greater Thickness T |

Lesser Thickness C Max |

Length A |

|||

| 15 | 0.15″ | 3.8mm | 0.032″ Max | 0.81mm | 7 5/8″ | 194mm |

| 13 | 0.13″ | 3.3mm | 0.032″ Max | 0.81mm | 6 5/8″ | 168mm |

| 11 | 0.11″ | 2.8mm | 0.032″ Max | 0.81mm | 5 5/8″ | 143mm |

| 9 | 0.09″ | 2.3mm | 0.028″ Max | 0.71mm | 5 1/8″ | 130mm |

| 7 | 0.07″ | 1.8mm | 0.028″ Max | 0.71mm | 4 1/8″ | 105mm |

| 5 | 0.05″ | 1.3mm | 0.024″ Max | 0.61mm | 3 5/8″ | 92mm |

All shims are designed and manufactured specially to suit the rail section for which they are required.

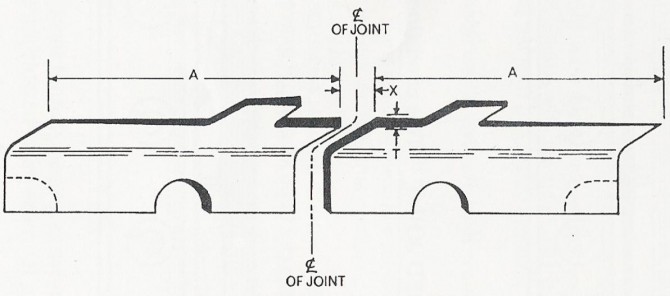

Space at centre of joint between the two pieces of half shim 11/16” to 3/4″ standard.

Four (4) pieces of half shims are required per joint, i.e. 2 left hand half shims and 2 right hand half shims.

When joint wear is equal, 4 pieces of the same size are used in the joint.

Where joint where is unequal, 2 pieces of one size and 2 pieces of another size are used in the joint.

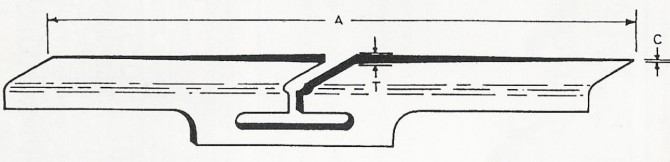

Type “F” Flexible Shim

Type “F” Flexible Shims are recommended for user where both rail ends at a joint show equal wear. This will particularly be the case on tracks where traffic travels in both directions. It is handier to use this type of shim rather than Type “HL” where possible, as a joint set comprises only 2 pieces.

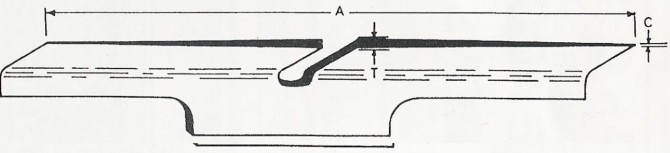

Type “S” Solid Lug Shim

The type “S” shims is recommended under conditions where rail is subject to considerable daily fluctuations in temperature.

Standard Dimensions (subject to our shop tolerances)

| Shim No | Greater Thickness T |

Lesser Thickness C Max |

Length A |

|||

| 15 | 0.15″ | 3.8mm | 0.032″ Max | 0.81mm | 16″ | 406mm |

| 13 | 0.13″ | 3.3mm | 0.032″ Max | 0.81mm | 14″ | 356mm |

| 11 | 0.11″ | 2.8mm | 0.032″ Max | 0.81mm | 12″ | 305mm |

| 9 | 0.09″ | 2.3mm | 0.028″ Max | 0.71mm | 11″ | 280mm |

| 7 | 0.07″ | 1.8mm | 0.028″ Max | 0.71mm | 9″ | 229mm |

| 5 | 0.05″ | 1.3mm | 0.024″ Max | 0.61mm | 8″ | 203mm |

All shims are designed and manufactured specially to suit the rail section for which they are required.

Special shims

Composite shims (to suit more than one rail section)

Double location shims (to suit different both centres)

Cranked shims (to clear electric bonding)

Others are designed and manufactured by us to suit special requirements