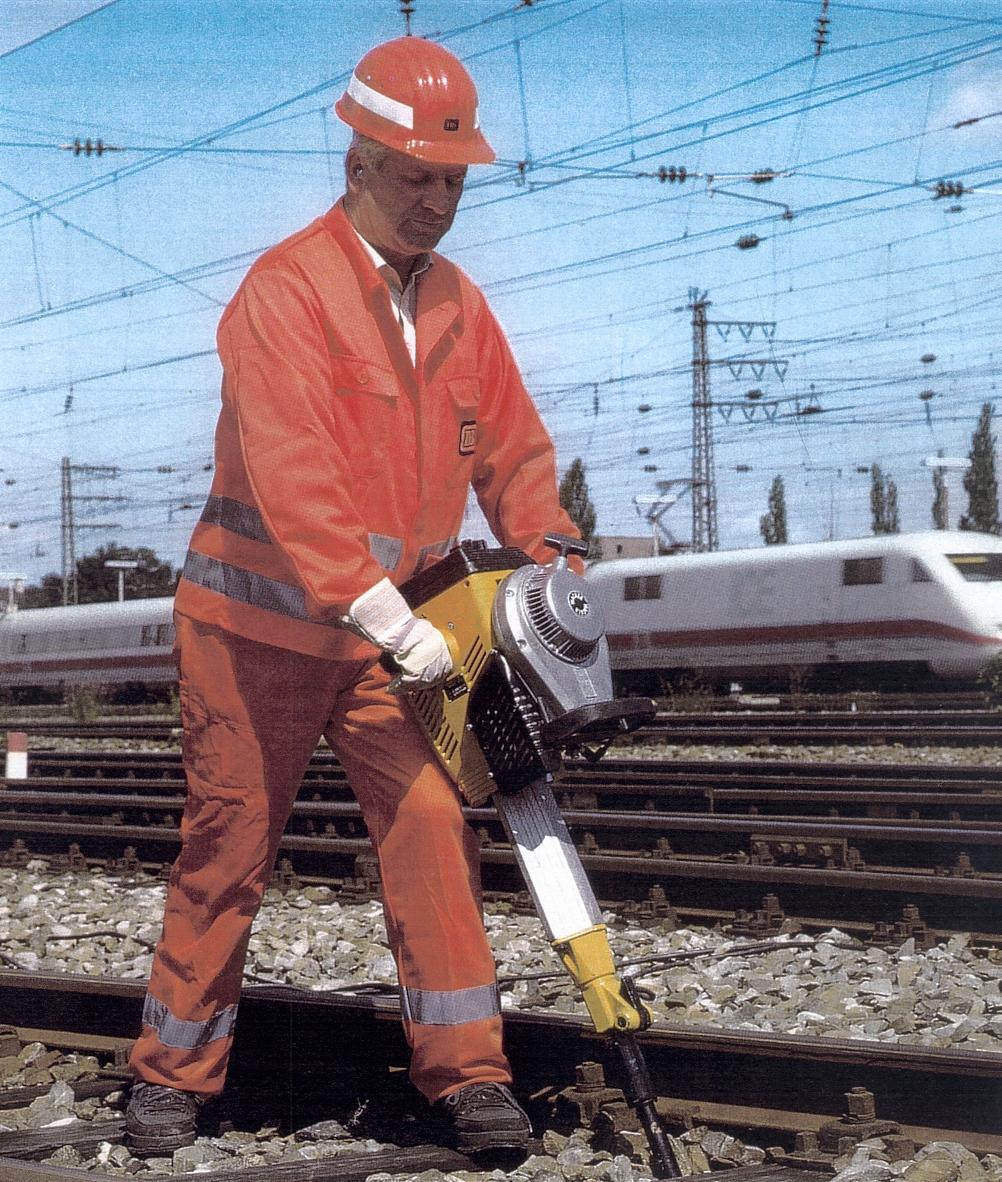

Petrol Tie Tamper BH23

Description of function

The engine, which is flanged to the crankcase and is held in place by 3 screws, drives the percussion system over a gear transmission and a connecting rod. The engine torque is transmitted by means of a centrifugal clutch.

The centrifugal clutch interrupts the flow of power to the percussion system at low engine speeds, thus allowing for a perfect idling of the engine.

The engine can be switched off with the stop button or the fuel tap.

The drive engine works according to the 2-stroke principle, and is started mechanically by means of a recoil starter. The engine is air-cooled and the air necessary for combustion is directed through the air filter.

| BH 23 EE 25 X 108 |

BH 23 EE 28 X 152 |

BH 23 EE 28 X 160 |

||

| Machine No. | 7741 | 7742 | 7743 | |

| Operating weight (mass) without tool | Kg: | 23 | ||

| Shaft for breaking tools | mm: | SW 25 x108 | SW 28 x 152 | SW 28 x 160 |

| Percussion rate | min-1: | 1300 – 1330 | ||

| Single stroke impact work (at tip of tool) |

(mkp): | 42 (4.2) | ||

| Power transmission | From engine via centrifugal clutch, crank mechanism, spring loaded percussion system to tool | |||

| Drive | 2-stroke petrol engine | |||

| Displacement | cm3: | 80 | ||

| Engine speed | min-1: | 4250 | ||

| Fuel Petrol-pol mixture: | 50 : 1 | |||

| Fuel consumption | l/h: | 1.2 | ||

| Tank capacity | l: | 1.8 | ||

The required vibration specification, called for by the EC Machine Regulations per Appendix 1, Paragraph 3.6.3a, was determined and measured while running the machine placed on the energy absorber and at nominal motor speed.

The weighted effective acceleration value, determined according to ISO 8662, Part 1, is 12.8 m/s2.